|

Main Products

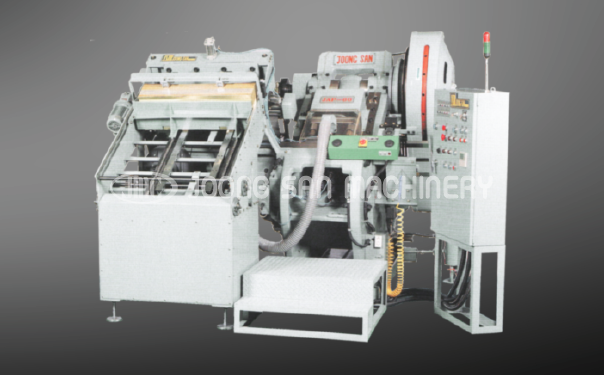

JOONG SAN is the only company today able to supply complete lines

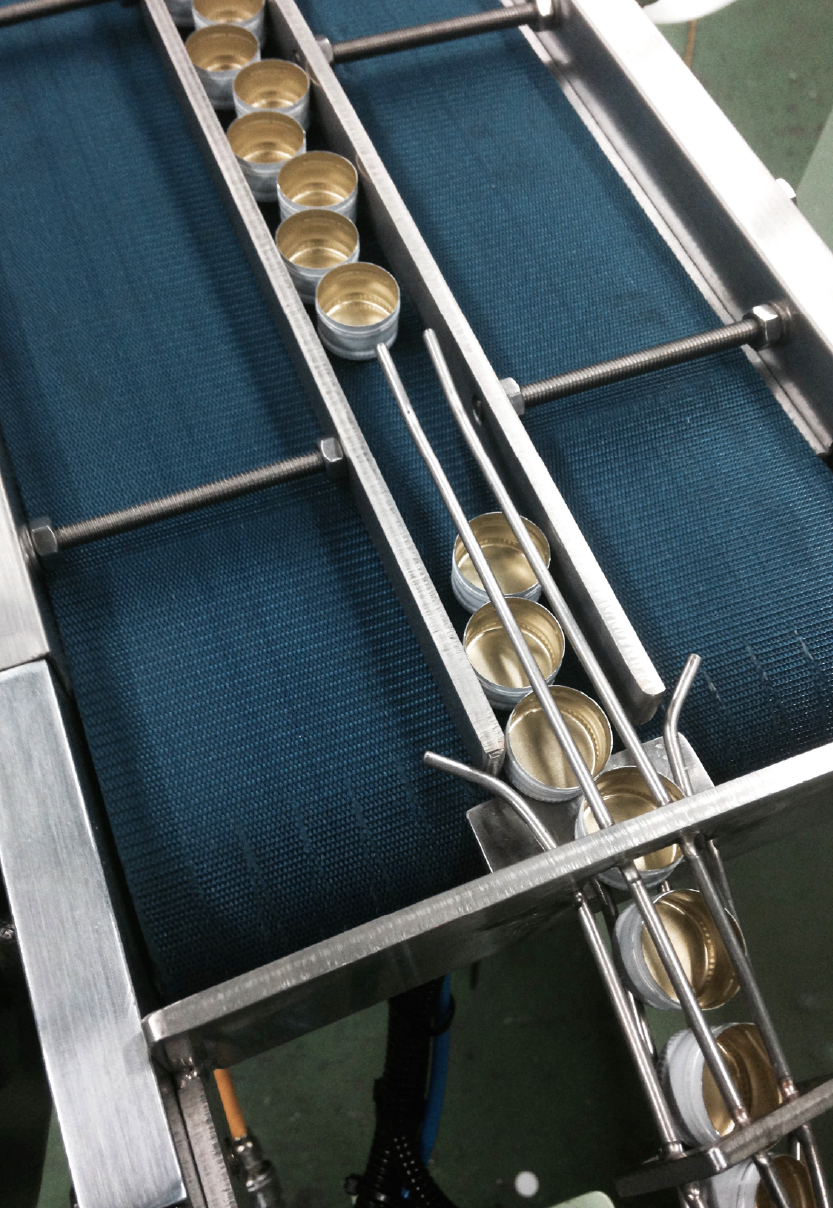

for the production of caps including draw, redraw, side decoration, roll-forming, top and side embossing, side shaving, as well as wad, liner and plastic pourer inserting. Our machines are designed to facilitate customer operation and improve productivity. It is fully automatic and its operation is very simple. With our production speed up to 400~450 caps per minute, the line is one of the fastest in the world today. Change parts are available for different size of caps and bottle diameter. Products are manufactured through various processes. Refer to Product flow sheets for more information.

How is an Aluminium ROPP cap made?

ROPP closures are made from a flat sheet of aluminium which then goes into a punching machine to give it its shape. The closures are put into a bulk hopper. The closures are then either blown by an air blower or a conveyor into the chute hopper. When the closures are in the chute hopper they are turned the correct way by a rotary disc or by vibration they are then fed down the capper chute upside down. The closures are turned as they go through the chute so they are the correct way up to be picked up by the container as it passes through the chute pickup.

What is a pourer insert in an Aluminium ROPP closure?

A Pourer insert is a 2 part pre-assemble made of HDPE that is inserted into a shell of a closures and retained by the retaining ring. A special bottle neck finish is required to retain the pourer during application.

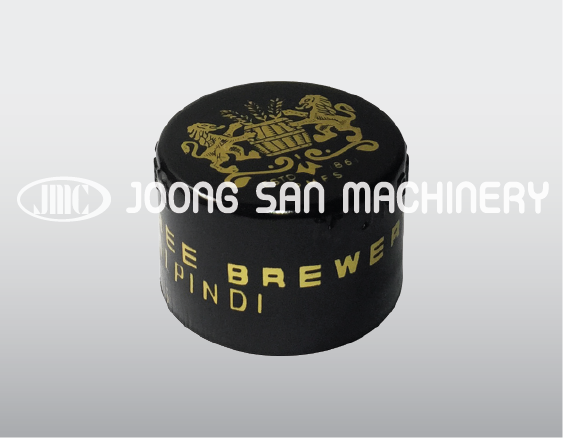

What is a LongCap (LC) and how are they made?

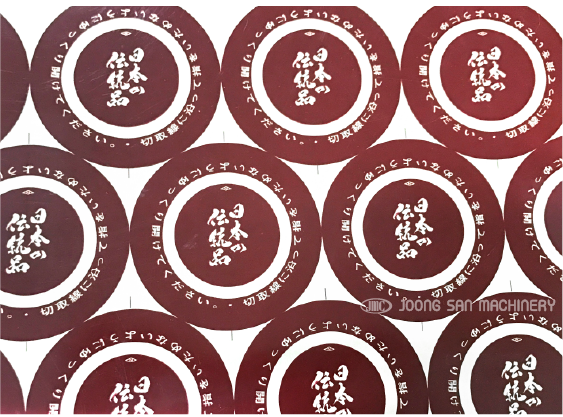

The LongCap is an aluminium screw cap closure and is deep-drawn from offset-printed aluminium sheets that are 0.22 to 0.24 mm thick. The deep-drawing takes place in two steps, in case of LC 30 x 60 mm in three steps. In the process, the aluminium is stretched so much that a print design on the side would no longer be recognizable. That's why a special side print method, similar to that for tubes, sleeves, etc., is used. Particular attention is given to the quality of this side print, since it also serves as an advertisement later when the product is on the shelf.

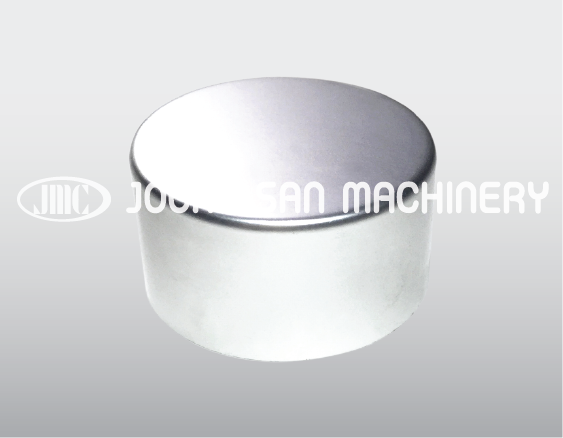

Products Description

| |